| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Vector

Model Number : VEC-VC-06033H-M-EA

Certification : CE

Place of Origin : China

MOQ : 1 kit

Price : To Be Discussed

Payment Terms : T/T, Western Union, L/C

Supply Ability : 500 kits/month

Delivery Time : 3-5 work days

Packaging Details : 280*208*78mm,375*290*155mm

Voltage : 220V

Power : 0.75KW

Phase : Single Phase

Communication Protocols : CanOpen/EtherCAT/ CanOpen

Encoder : 17 23 / 24bit Tamagawa absolute encoder;

Rated Current : 6A

Input/Output : Pulse/Analog

Control Mode : Position / Speed / Torque

Application : Food packing machine

Product Name : 220V 750 Watt Servo Drive

220V 750 Watt Servo Drive Single Phase Servo Motor With 3M / 5M Cable

Products Description

| Product Name | 220V 750 Watt Servo Drive |

| Brand | Vector |

| Model No. | VEC-VC1-00623M-M-E |

| Power | 0.75KW |

| Input/Output | Pulse/Analog |

| Voltage | 220V |

| Phase | Single Phase |

| Rated Current | 6A |

| Communication Protocols | CanOpen / EtherCAT / Modbus |

| Encoder | 17 / 23 / 24 bit absolute encoder; |

Wiring precautions

● It is recommended not to use single-phase 220V for main power supply,

which may cause damage to electrolytic capacitor due to lack of phase.

● Do not change the wiring during power-on, otherwise it may cause electric

shock or injury.

● Please perform wiring or inspection by professional technicians, otherwise it

may cause electric shock or product failure.

● Please carefully confirm the wiring and power supply. The output circuit

may be short-circuited due to wiring errors or application of different voltages.

The brake does not operate when the above fault occurs, which may result in mechanical damage or personal injury.

● Do not connect the input power cable to the U, V, and W terminals of the

drive. Otherwise, the servo driver will be damaged.

● When wiring, do not pass the power cable and signal cable through the same

pipe, and do not bundle them together. The distance between the two should be more than 30cm to avoid interference.

● The driver ground terminal must be grounded to avoid leakage and reduce

the interference of the system, and the diameter of the ground wire should be the same as or above the power supply line.

● When connecting the AC power supply and DC power supply to the servo unit, connect to the specified terminal.

Failure to do so may result in malfunction or fire.

● For the wiring length, the command input line is up to 3m and the encoder

line is up to 20m.

● Use a twisted-pair shielded cable for the signal cable and encoder cable, and

ground the shield with a single end.

●The U, V, W terminals of the driver and the U, V, and W terminals of the

motor should be connected one by one according to the name. If it is wrong connected, the motor cannot operate normally.

● Common DC bus products require pressure sensitive resistors and the wiring

is secure.

● Please check the power after the power is off for at least 5 minutes. Even if

the power is turned off, high voltage may remain inside the servo drive. Therefore, do not touch the power terminal within

5 minutes after the power is turned off, otherwise it may cause electric shock.

● Do not turn the power ON/OFF frequently. When it is necessary to

continuously turn ON/OFF the power, please control it once or less in 1 minute. Since the power supply section of the

servo driver has a capacitor, a large charging current (charge time of 0.2 seconds) flows during the ON/OFF power supply.

Therefore, if the power is turned ON/OFF frequently, the performance of the main circuit components inside the servo driver

will be degraded.

● Do not apply power when the terminal block screws are loose or the cable is

loose. Otherwise, it may cause fire.

● Take appropriate shielding measures in the following locations, otherwise

the machine may be damaged:

1. Locations that cause interference due to static electricity;

2. A place that produces a strong electric field or a strong magnetic field;

3. Locations where there may be radiation radiation;

4. A place with a power cord nearby.

| Installation Environment Requirements | Atmospheric Pressure | 86~106kPa |

| Mbient Humidity | 0~55℃ | |

| Ambient Temperature | 0~90%RH | |

| IP Rating | IP20 | |

| Vibration | 0~4.9m/s^2 |

Maintenance and inspection Precautions

● do not change the wiring while the power is on, otherwise it may cause electric shock or injury.

● please perform wiring or inspection by professional technicians, otherwise it

may cause electric shock or product failure.

● please check the power after the power is off for at least 5 minutes. Even if the power is turned off,

high voltage may remain inside the servo drive. Therefore, do not touch the power terminal within 5 minutes

after the power is turned off, otherwise it may cause electric shock.

●when replacing the servo drive, please back up the servo driver user parameters to be replaced before the

replacement, and transfer the backup to the new servo drive, and then restart the operation, otherwise the

machine may be damaged.

Other Questions:

Q1. How to select the suitable model?

A: Please confirm your requirements for Rated Power, Current, Voltage,

Torque and select the suitable model based our model list;

Q2. How to set the programming system?

A: Our Servo drive support the Global Communication protocols: Modbus/CANopen/EtherCAT,

Please Just make the programming follow your experiences;

Certificates

1. CE (EU Safety Standard);

2. IEC/EN61800-5-1:2007 (Safety requirements for electrical, thermal and energy in Section 5-1 of the

variable speed electric driver system), corresponding to the national standard GB12668.501-2013;

3, IEC / EN61800-3: 2004 + A1 (speed control electric driver system part 3 electromagnetic compatibility

standards and its specific test methods), corresponding to the national standard GB12668.3-2012.

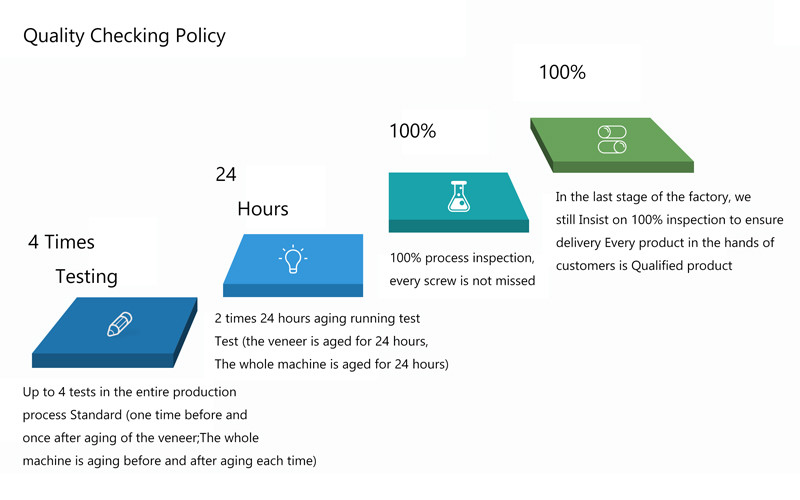

Quality Checking:

Four times Production testing

Two Times 24 hoursTesting

100% Inspection Before Shipping

Delivery Time and Shipping Way

1. For small order we always can delivery out within 1 week.

2. Our products can be shippied via Air, Land or Sea.

| Packing details of Servo Drive | |||

| Products | E1(3-6A) | E2(7-12A) | E3(16-27A) |

| Ctn. Size | 280*208*78 | 280*208*112 | 375*290*155 |

Our Team:

|

|

Single Phase 750 Watt Multi Axis Servo Drive With 3M 5M Cable Images |